Effect of stir-frying on oat milling and pasting properties and rheological properties of oat flour |

| |

| Affiliation: | 1. CONICET-UNC. Instituto de Ciencia y Tecnología de Alimentos Córdoba (ICYTAC), Argentina;2. Universidad Nacional de Córdoba; Facultad de Ciencias Exactas, Físicas y Naturales; Instituto de Ciencia y Tecnología de los Alimentos; Córdoba, Argentina;3. Universidad Nacional de Córdoba. Instituto Superior de Investigación, Desarrollo y Servicios en Alimentos, SeCyT. Argentina;1. Department of Food and Environmental Sciences, University of Helsinki, Latokartanonkaari 11, P.O. Box 27, FI-00014, Finland;2. VTT Technical Research Centre of Finland, Tietotie 2, P.O. Box 1000, FI-02044, Espoo, Finland;1. Wageningen UR Plant Breeding, Wageningen University and Research Centre, P. O. Box 386, NL-6700 AJ Wageningen, The Netherlands;2. Bioscience, Wageningen University and Research Centre, P.O. Box 16, NL-6700 AA Wageningen, The Netherlands;3. Allergy Consortium Wageningen, P.O. Box 16, NL-6700 AA Wageningen, The Netherlands;4. Wageningen UR Food Chemistry, Wageningen University and Research Centre, P. O. Box 8129, NL-6700 EV Wageningen, The Netherlands |

| |

| Abstract: |

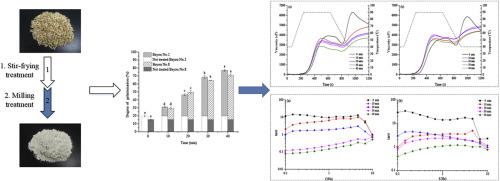

Stir-frying, similar to roasting, is a key step for oat milling process in China. The oat flour milling yield of Bayou No.2 and Bayou No.8 and their corresponding flour quality were investigated under different processing conditions (160 °C, for 0, 10, 20, 30 and 40 min). Results showed that oat flour milling yield was increased after stir-frying, Bayou No.2 and Bayou No.8 reached the highest yield after a 10 min and 20 min of stir-frying, which were 45.40% and 52.96%, respectively. With the increasing of stir-frying time, the gelatinization degree and the particle size of oat flour gradually increased, while their angle of repose and L* values were reduced. RVA studies showed that the stir-fried oat flour exhibited lower peak, trough, breakdown and setback viscosities compared to not stir-fried oat flour, indicating that stir-fried oat flour formed a more stable network structure and stir-frying induced an inhibitory effect on the retrogradation of oat flour paste. Rheological analysis suggested that the low tanδ of stir-fried oat flour than that of not stir-fried oat flour, revealing that the stir-fried oat flour paste exhibited more elastic but less viscous behavior. |

| |

| Keywords: | Oat flour Stir-frying Flour yield Flour properties |

| 本文献已被 ScienceDirect 等数据库收录! |

|